Analogue input 3 (9033) / 6 (9015 / EX-9036) Channel module (16 bit)

14.09.2012 - Version 1.00

- Introduction

- Technical data

- Sensors

- Applications

- Block diagram

- Pin assignment

- Factory settings

- LED-display

- INIT/Configuration mode

- Implementation

- Calibration

- Connections

- Appendix A.1 Modbus commands

- Appendix A.2 DCON commands

- Appendix A.3 Host Watchdog commands

- Links

Introduction

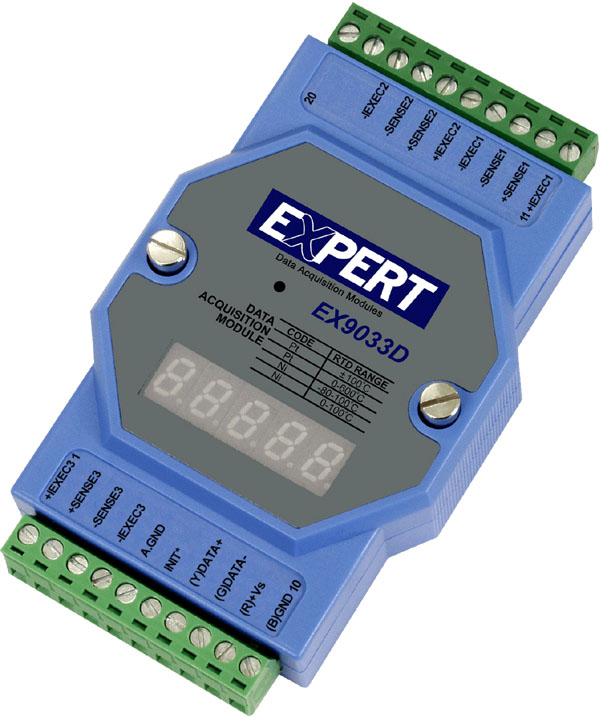

The EX-9015 / EX-9033 / EX-9036 Remote IO Module is a high quality and cost-effective data collection device. ExpertDAQ remote IO modules allow virtually unlimited and completely transparent the expansion of PLCs with analog inputs via EIA485 / RS485 (optional with MODBUS RTU communication protocol). RS485 is the industry's most widely used bi-directional half-duplex bus with symmetric transmission. It allows sending and receiving high data rates over long distances.

The EX-9015 / EX-9033 / EX-9036 analogue input modules have been developed for the detection of resistance temperature sensors and can be used with all popular resistance thermometers (see table Implementation) The EX-9033 provides 3 available channels, the Models EX-9015/EX-9036 have six inputs each. The modules with designation EX-9033P/EX-9036P and the EX-9015 also possess individually configurable inputs. All modules are available with Modbus RTU communication protocol.

Technical data

|

9015 |

9033 |

9033P |

9036 |

9036P |

|

|

Resolution |

16 bit |

||||

|

Inputs (differential) |

6 |

3 |

3 |

6 |

6 |

|

Sample rate |

12 Hz |

10 Hz |

10 Hz |

12 Hz |

12 Hz |

|

Sensors |

resistance temperature sensor Pt, Cu, Ni |

||||

|

Isolation |

3000V |

||||

|

Power supply |

10 V - 30 VDC |

||||

|

Energy consumption |

1,1W |

1,0W |

1,0W |

1,1W |

1,1W |

|

Operating temperature |

-25°C bis +75°C |

||||

|

Single channel configuration |

yes |

no |

yes |

no |

yes |

|

Dual Watchdog Timer |

yes |

||||

Measuring ranges

The EX-9015 / EX-9033 / EX-9036 have been developed for the recording of data from temperature sensors. The following sensors are supported:

- Pt100 a=0.003916

- Pt100 a=0,00385

- Ni120 a=0,00672

- Pt1000 a=0.00385

- Cu100 a=0.00421

- Cu100 a=0.00427

- Cu1000 a=0.00421

- Cu50

- Ni100

Applications

ExpertDAQ remote IO modules are used in a variety of applications in industrial environments:

- Machine control and automation

- SCADA-System

- Heating, ventilation, air conditioning and refrigeration

- Remote measurement, monitoring and control

- Security and alarm systems

- Building control

- Process visualisation

- Data processing

- Process control

Block diagram

EX-9015 / EX-9033 / EX-9036

Pin assignment

The connection of voltage supply, data cables and the analog inputs take place via two 10-pin screw terminal connectors. The following table shows the pin assignment::

|

Pin |

name |

Description |

only EX-9015 / EX-9036 |

|

1 |

+SENSE3 |

Sensor input channel 3+ |

only EX-9015 / EX-9036 |

|

2 |

-SENSE3 |

Sensor input channel 3- |

only EX-9015 / EX-9036 |

|

3 |

A GND |

Sensor input Earth |

only EX-9015 / EX-9036 |

|

4 |

+SENSE4 |

Sensor input channel 4+ |

only EX-9015 / EX-9036 |

|

5 |

-SENSE4 |

Sensor input channel 4- |

only EX-9015 / EX-9036 |

|

6 |

A GND |

Sensor input Earth |

only EX-9015 / EX-9036 |

|

7 |

+SENSE5 |

Sensor input channel 5+ |

only EX-9015 / EX-9036 |

|

8 |

-SENSE5 |

Sensor input channel 5- |

only EX-9015 / EX-9036 |

|

9 |

A GND |

Sensor input Earth |

only EX-9015 / EX-9036 |

|

10 |

INIT* |

INIT Pin |

|

|

11 |

(Y) DATA+ |

RS485 Data line + |

|

|

12 |

(G) DATA- |

RS485 Date line - | |

|

13 |

(R) +Vs |

Power supply | |

|

14 |

(B) GND |

Earth |

|

|

15 |

IEXC0+ |

Power supply channel 0+ |

|

|

16 |

SENSE0+ |

Sensor input channel 0+ |

|

|

17 |

SENSE0- |

Sensor input channel 0- |

|

|

18 |

IEXC0- |

Power supply channel 0- |

|

|

19 |

A GND |

Sensor input earth |

|

|

20 |

IEXC1+ |

Power supply channel 1+ |

|

|

21 |

SENSE1+ |

Sensor input channel 1+ |

|

|

22 |

SENSE1- |

Sensor input channel 1- |

|

|

23 |

IEXC1- |

Power supply channel 1- |

|

|

24 |

A GND |

Sensor input earth |

|

|

25 |

IEXC2+ |

Power supply channel 2+ |

|

|

26 |

SENSE2+ |

Sensor input channel 2+ |

|

|

27 |

SENSE2- |

Sensor input channel 2- |

|

|

28 |

IEXC2- |

Power supply channel 2- |

Please refer to the section Connections to the correct connection of the terminal

Factory settings

|

Name |

Description |

|

Baud rate |

9600 |

|

Data bits |

8 |

|

Parity |

keine |

|

Stop bit |

1 |

|

Device address |

1 |

|

Sensor |

Type 20 resistance thermometer |

The settings are easy to change using the supplied software “9000 utility”

LED display

The EX-9015 / EX-9033 / EX-9036 are equipped with a 4.5-digits 7-segment display, which indicates the important information

INIT configuration mode

The EX-9015 / EX-9033 / EX-9036 features EEPROM, in which parameters such as device address, model, baud rate, range and other information is stored. Before commissioning the parameters usually need to be adjusted. For this purpose, the INIT mode has to be activated as follow:

- Turn off the module

- Connect the INIT pin to the GND pin

- Turn on the module

The device is now ready to configure

Implementation

The following table shows the minimum and maximum range of the six measuring ranges:

|

Measuring ranges |

min |

max |

min |

max |

|

Pt100 α=0,00385 |

-100 |

100 |

-100 |

100 |

|

Pt100 α=0,00385 |

0 |

100 |

0 |

100 |

|

Pt100 α=0,00385 |

0 |

200 |

0 |

100 |

| Pt100 α=0,00385 |

0 |

600 |

0 |

100 |

| Pt100 α=0,003916 |

-100 |

100 |

-100 |

100 |

|

Pt100 α=0,003916 |

0 |

100 |

0 |

100 |

|

Pt100 α=0,003916 |

0 |

200 |

0 |

100 |

|

Pt100 α=0,003916 |

0 |

600 |

0 |

100 |

|

Ni120 |

-80 |

100 |

-80 |

100 |

|

Ni120 |

0 |

100 |

0 |

100 |

|

Pt1000 α=0,00385 |

-200 |

600 |

-33,3 |

100 |

|

Cu100 α=0,00421 |

-20 |

150 |

-13,3 |

100 |

|

Cu100 α=0,00427 |

0 |

200 |

0 |

100 |

|

Cu1000 α=0,00421 |

-20 |

150 |

-13,3 |

100 |

|

Pt100 α=0,00385 |

-200 |

200 |

-100 |

100 |

|

Pt100 α=0,003916 |

-200 |

200 |

-100 |

100 |

|

Pt100 α=0,00385 |

-200 |

600 |

-33,3 |

100 |

|

Pt100 α=0,003916 |

-200 |

600 |

-33,3 |

100 |

|

Cu50 |

-50 |

150 |

-33,3 |

100 |

|

Ni100 |

-60 |

180 |

-33,3 |

100 |

The EX-9015/EX 9033/EX-9036 has all measuring ranges with a resolution of 16 bits. To achieve the best accuracy select the range that suits your application best.

Calibration

NOTE: The calibration must be performed by qualified personnel!

- Calibration precedure:

- Install the zero point calibration resistor

- Allow the module to warm up at least 30 min

- Enter the sensor’s type designation for which you want to perform the calibration (see table)

- Activate the calibration

- Run the zero point calibration

- Install the span calibration resistor

- Run the span calibration command

- Repeat steps 4 through 7 three times

- Notes:

- Use 2-wire sensor connections to the resistance calibration

- For EX-9033 / EX9036 connect the calibration resistor on channel 0

- For EX-9015 / EX9033P / EX9036P each channel should be individually calibrated while the other channels are disabled during the calibration.

- Prior the calibration reset the communication protocol.

- For calibration use the following resistors:

|

Type |

Zero calibration |

Span calibration |

|

20 |

0 Ω |

320 Ω |

|

2A / 2D |

0 Ω |

320 Ω |

Connections

- Connection recommendations

- For EX-9033 / EX-9036 and EX-9033P / EX-9036P the connections of individual channel have to be shielded and the shield to be connected to the port A.GND of the channel.

- For EX-9015 shielded wires are recommended. The shield should be connected to the IEXEC+ terminal of the channel.

- For RS-485 use twisted wire pairs (24AWG)

- Use 26-12AWG wire for signal connections

Please note that the channels 0 to 2 of EX-9015 / EX-9036 are designed for 2 / 3 / 4 wire connections. However channels 3 to 5 can only read 2 or 3 wire connections. On the EX-9033 all channels allow 2 / 3 / 4 wire connections.

When connecting inputs 0 to 5 please follow the graphics below:

2-wire connection

3-wire connection

4-wire connection

If you leave the measurement range, you will be indicated as follow:

|

Outputformat |

Below the minimum value |

Over the maximum value |

|

Scientific |

-9999,9 |

9999,9 |

|

% FSR |

-999,99 |

999,99 |

|

Two's complement HEX |

7FFF |

8000 |

Appendix A.1 - Modbus commands

Inquiry:

|

00 |

Address |

1Byte |

1 bis 247 |

|

01 |

Function code |

1Byte |

0x04 |

|

02-03 |

Start channel |

2 Byte |

0 bis 7 for reading the analogue inputs |

|

04-05 |

Number of input channels (N) |

2Byte |

1 bis 8;(Start channel+N)<=8 for reading the analogue inputs |

Output:

|

00 |

Address |

1Byte |

1 bis 247 |

|

01 |

Function Code |

1Byte |

0x04 |

|

02 |

Byte counter |

1 Byte |

2 x N |

|

03~ |

Data of the input channel |

2 x N Bytes |

Error output:

|

00 |

Address |

1Byte |

1 to 247 |

|

01 |

Function code |

1Byte |

0x84 |

|

Exception Code |

1 Byte |

02:Start channel outside the range 03:(Start channel+number of input channels) out of range, incorrect number of bytes received |

Addressing:

|

|

EX-9015-M / EX-9033-M / EX-9036-M |

|||

|

Address |

Hex |

Channel |

Content |

Attribute |

|

30001 |

0H |

0 |

Analogue input value |

Read |

|

30002 |

1H |

1 |

Analogue input value |

Read |

|

30003 |

2H |

2 |

Analogue input value |

Read |

|

30004 |

3H |

3 |

Analogue input value |

Read |

|

30005 |

4H |

4 |

Analogue input value |

Read |

|

30006 |

5H |

5 |

Analogue input value |

Read |

|

30007 |

6H |

6 |

Analogue input value |

Read |

|

30008 |

7H |

7 |

Analogue input value |

Read |

Appendix A.2 - DCON commands

|

Command |

Output |

Description |

|

%AANNTTCCFF |

!AA |

Set the module configuration |

|

#** |

No reply |

Synchronised sampling |

|

#AA |

>(Data) |

Reads all analogue inputs of all channels |

|

#AAN |

>(Data) |

Reads analogue input of specific channels |

|

$AA0 |

!AA |

Performs a span calibration |

|

$AA1 |

!AA |

Performs a zero calibration |

|

$AA0Ci |

!AA |

Performs a zero calibration on a specific channel |

|

$AA1Ci |

!AA |

Performs a span calibration on a specific channel |

|

$AA2 |

!AANNTTCCFF |

Reads the module configuration |

|

$AA3 |

>(Data) |

Reads the DJC temperature |

|

$AA4 |

>AAS(Data) |

Reads synchronised data |

|

$AA5VV |

!AA |

Enable / disable the channel |

|

$AA6 |

!AAVV |

Reads the state of the channel (active/inactive) |

|

$AA7CiRrr |

!AA |

Sets the configuration of a channel |

|

$AA8Ci |

!AACiRrrr |

Reads the configuration of a channel |

|

$AA9 |

!AA(Daten) |

Reads the CJC Offset |

|

$AA9SNNNN |

!AA |

Sets the CJC Offset |

|

$AAA |

>(Data) |

Reads the analogue input of all channels in HEX format |

|

$AAA |

!AAi |

Reads the CJC update settings |

|

$AAAi |

!AA |

Sets the CJC update settings |

|

$AAB |

!AANN |

Reads the diagnostic status of a channel |

|

$AAF |

!AA(Daten) |

Reads the firmware version |

|

$AAM |

!AA(Daten) |

Reads the module name |

|

$AAP |

!AASC |

Reads the protocol |

|

$AAPN |

!AA |

Specifies the protocol |

|

$AAS0 |

!AA |

Internal calibration |

|

$AAS1 |

!AA |

Loads the factory settings for the calibration parameters |

|

~AAC |

!AAN |

Reads the CJC status (active/inactive) |

|

~AACN |

!AA |

Enables/disables CJC |

|

~AAEV |

!AA |

Enables/disables the calibration |

|

~AAI |

!AA |

Soft INIT |

|

~AAO(Name) |

!AA |

Specifies the module name |

|

~AATnn |

!AA |

Sets the soft INIT timeout |

|

~AAEE |

!AAN |

Reads open inputs |

|

~AAEEN |

!AA |

Enables/disables detection of open inputs |

|

@AAS |

!AAN |

Reads the connection mode |

|

@AASN |

!AA |

Sets the connection mode to differential or single-ended |

Appendix A.3 - Host Watchdog commands

|

Command |

Output |

Description |

|

~** |

No reply |

Host OK |

|

~AA0 |

!AASS |

Reads the Host Watchdog status |

|

~AA1 |

!AA |

Sets the Host Watchdog status back |

|

~AA2 |

!AAETT |

Reads the Host Watchdog timeout setting |

|

~AA3ETT |

!AA |

Sets the Host Watchdog timeout settings |

Links

- EX-9015

6-channel, 16-bit RS485 analogue In module detector with single channel configruation for resistive temperature detector - EX-9015-M

6-channel, 16 bit RS485 Modbus RTU Analogue In Module with single channel configruation for resistive temperature detector - EX-9033

6-channel, 16 bit RS485 Analogue In Module for resistive temperature detector - EX-9033-M

6-channel, 16 bit RS485 Modbus RTU Analogue In Module for resistive temperature detector - EX-9033P

6-channel, 16 bit RS485 Analogue In Module with single channel configruation for resistive temperature detector - EX-9033P-M

6-channel, 16 bit RS485 Modbus RTU Analogue In Module with single channel configruation for resistive temperature detector - EX-9036

6-channel, 16 bit RS485 Analogue In Module for resistive temperature detector - EX-9036-M

6-channel, 16 bit RS485 Modbus RTU Analogue In Module for resistive temperature detector - EX-9036P

6-channel, 16 bit RS485 Analogue In Module with inpidual channel configuration for resistive temperature detector - EX-9036P-M

6-channel, 16 bit RS485 Modbus RTU Analogue In Module with inpidual channel configuration for resistive temperature detector